Meeting the infection control challenge when selecting a support surface

Healthcare settings face the challenge of managing an effective Infection Control protocol on a daily basis. Ensuring the safety of patients and staff at all times, in a range of different settings requires a robust process, where care and treatment can be delivered without the risk of infection due to poor hygiene standards.

With the COVID-19 global pandemic, now more than ever, there is a ‘spot- light’ on infection control, and what can be done to mitigate the spread of viruses and pathogens. Staff and facilities are under immense pressure to ensure the best standard of care, ensuring effective infection control, but often constrained by the same amount of resources they have had in the past.

What can be done in terms of selecting equipment that withstands the demands of an effective infection control regime? Does it make a difference when selecting a support surface what type of product is chosen?

"What should be considered to combat the infection control challenge?"

There are some key considerations that should be undertaken when making the selection of an appropriate support surface to ensure best practice for Infection Control. Products should be designed to meet the needs of demanding cleaning regimes that are rigidly followed in healthcare facilities to ensure patient safety. Design criteria focusses on 2 main areas when considering infection control standards; the cover fabric selected and the way the material is constructed to protect the inner core of a mattress.

Welded Seams

The way the material is constructed around the perimeter of any mattress can play a big part in how effective it is against the risk of bodily fluids and other hazards leaking into the inner mattress core. It is widely recognised that using a mattress that has “welded” rather than sewn seams can offer better protection against fluid ingress. Whereas sewing perforates the mattress cover with tiny holes, welding actually bonds the fabric together so the join cannot be penetrated. Selecting a mattress that has welded rather than sewn seams can be a good first step in ensuring high standards in infection control for your surface inventory.

Cover Fabric

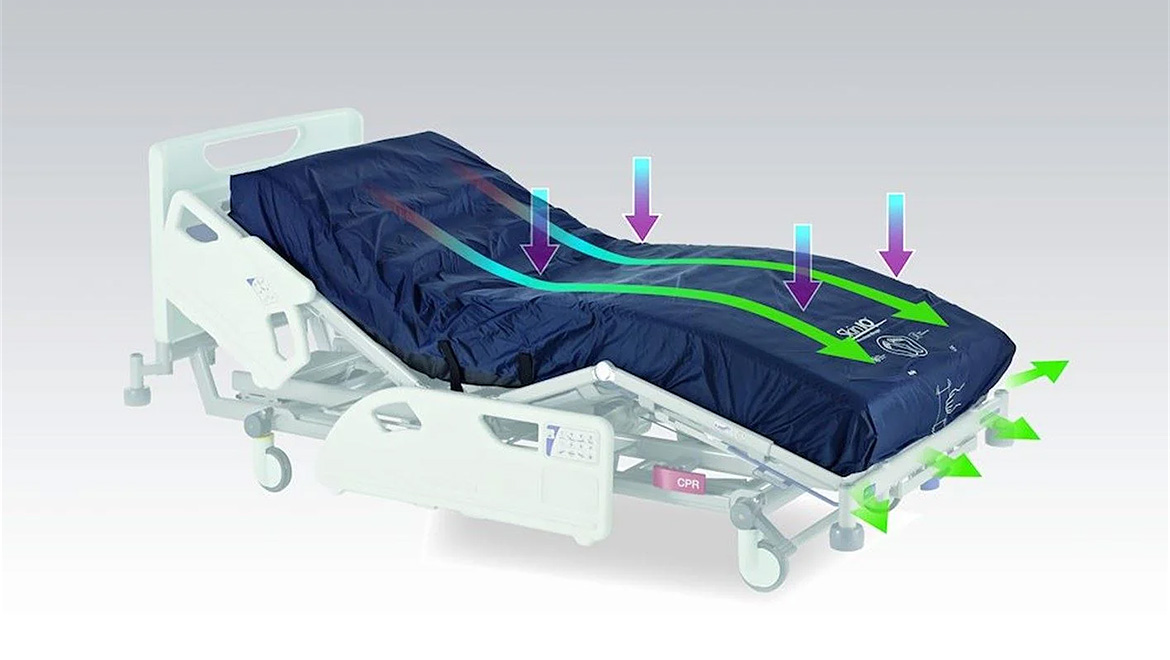

The cover fabric selected for a support surface can have a major impact on the performance of the surface itself in terms of; pressure redistribution, immersion and envelopment and the impact it has on microclimate at the skin interface. The fabric selected for the cover must address these characteristics, as well as offer a high level of protection against ingress to the inner mattress core. Through its lifetime a cover will be subject to regular using a range of methods and many different types of cleaning chemicals. How can you be sure that a surface cover has all the qualities it needs to meet all these different needs?

When selecting the cover material the durability should be evaluated in terms of its resistance to the abrasive action of cleaning, and very importantly its resistance to the many chemicals that are used as part of a healthcare facility cleaning regime. If covers can be resistant in this area, they are less likely to start breaking down, causing micro cracks to appear, that may not be visible to the naked eye, but can compromise the cover over time and allow for the seeping of bodily fluids and other hazards into the mattress.

It is also important to always follow the cleaning guidance for a surface, from the manufacturer’s instructions for use, and check for compatibility of cleaning chemicals that are being used. Regular mattress inspections that check for any compromises in the surface cover are also recommended as best practice to ensure a good standard of care in a facility.

_Blog%20Image_PNG.png)

_Blog%20Image_PNG.png)